High Pressure Services

Specialists in Cerakote Ceramic Coatings

Unit 3B Honeywood House

Enterprise Zone

Whitfield, Dover, Kent CT16 3EH

Phone: 07850 172258

Office: 01304 821796

Email: hpsdover@btinternet.com

Cerakote Ceramic Coating

CERAKOTE® FOR 3D PRINTING

CERAKOTE® FOR ARCHERY

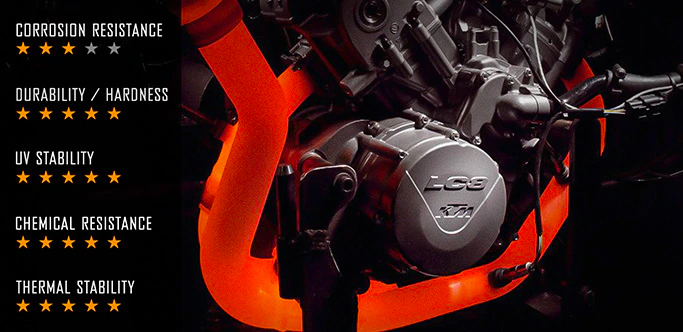

CERAKOTE® FOR AUTOMOTIVE

A quest to develop a high-temperature coating resulted in the development of the world’s highest quality ceramic-based thin film automotive coatings.

CERAKOTE® FOR BICYCLES

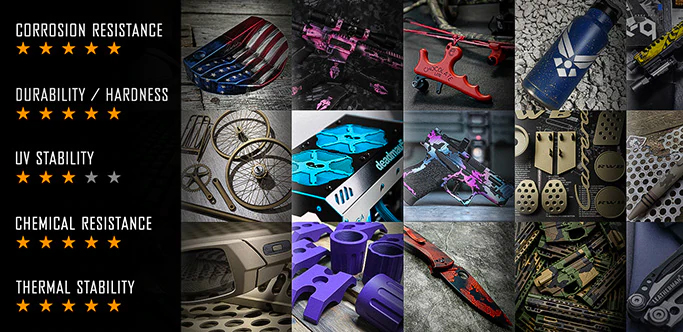

Cerakote® surpasses anodizing, powder coating, and other paint-based OEM finishes. Specifically, in these areas:

-

The thin film ceramic polymer coating provides unsurpassed corrosion resistance in the harshest environments. -

A ceramic coating of military-grade outlasts any other finish by a long shot. -

Exceptional adhesion to virtually any non-rubberised substrate.

-

Thin film technology: Cerakote’s smooth finish offers properties such as hydrophobic, anti-seize, and low coefficient of friction.

-

Our product line is available in hundreds of unique colors! Even with a variety of substrate materials, color consistency is incredibly accurate. Our in-house color development team can create custom color options for you. -

Cerakote® applicators and creative outlets enable endless design possibilities. In-house colour development allows us to provide brands with custom color options.

PROPERTIES THAT MAKE CERAKOTE® IDEAL FOR KITCHEN AND BATH FIXTURES

- ULTRA DURABLE CERAMIC FINISH

- UNMATCHED RESISTANCE TO ALL HOUSEHOLD AND COMMERCIAL CLEANERS

- LUXURIOUS LOOK AND FEEL

- CONSISTENT FINISH AND COLOR

- EASY TO CLEAN & SANITIZE CERAMIC FINISH

- OVER 100 DESIGNER COLORS AND FINISHES

- ENVIRONMENTALLY FRIENDLY ALTERNATIVE TO PLATING AND OTHER TREATMENTS

- LOW COST APPLICATION FOR SMALL BATCH OR LARGE RUN

- TIMELESS, DURABLE, AFFORDABLE & SUSTAINABLE

CERAKOTE® is an ultra-durable ceramic finish ideal for kitchen and bath fixtures. It allows greater design potential without sacrificing performance. Cerakote’s broad range extends from bright whites to unique metallic finishes, making it possible for your fixtures to fit seamlessly into every design style.

CERAKOTE® combines the performance qualities expected in a commercial setting with the look and feel of a bespoke hospitality design. It is impervious to virtually every cleaner, while maintaining a surface that is both beautiful to look at and to touch. CERAKOTE® will endure the test of time while remaining a prominent design statement.

The beauty and performance of CERAKOTE® are just the beginning. The cost and ease of application are in many cases less than plating and other metal treatments when accounting for the total applied cost of these traditional treatments. Furthermore, CERAKOTE® is an environmentally friendly alternative to many of these options which can have a heavy impact on our environment.

When performance, beauty, color and cost matter, Finish Strong with Cerakote® Ceramics.

Cerakote® ceramic coatings increases the longevity of parts by adding the industries best corrosion protection in an ultra-durable thin film coating. While other coatings claim big corrosion numbers, they simply don’t deliver on the parts that matter most.

Tight tolerance parts such as threads and valves are generally left uncoated due to the tolerance limitations of thick paints, powder coatings and plasma spray. This leaves the most critical areas of your operation exposed and unprotected. Not only does Cerakote® have the industry’s leading corrosion protection, it can also be applied to the entire part (external and internal without the need for expensive masking), including the most difficult threads, valves, and impellers.

CERAKOTE® IS KNOWN FOR:

Unmatched corrosion protection- at 1 mil thickness our coatings surpass 4,000 hrs. of salt spray corrosion testing (ASTM B117) without failure.

Excellent chemical protection – ideal for exposure to acids, alkaline solutions, drilling fluid, crude oils and byproducts, hydraulic fluids and more.

Excellent abrasion resistance – handles high cycling, high wear environments. Rates 9H hardness and over 5,000 cycles per mil of abrasion resistance (ASTM D4060).

Flexibility – Cerakote’s thin film design allows the coating to flex with the substrate. Great for thermal expansion and high vibratory environments.

No masking required – Save time and money by eliminating costly masking during the coating process.

Tight tolerance applications – excellent for use on threads, fasteners, values, pumps, and internals where paint and powder coating cannot be applied.

High temperature applications – Coatings formulated to withstand temperatures up to 1,800° F, including thermal shock resistance, with no adverse effects.

Superior low coefficient of friction – CoF of 0.11 that exceeds current market PTFE coatings.

Companies around the world use Cerakote® for its industry leading chemical resistance, corrosion protection, durability, and tight tolerance finishes. Cerakote® is applied to 100% of your part without any masking, which provides you with industry leading protection and durability without exception.

This testimony is from one of our customers in the Permian Basin that tested our products in the field and made the switch to Cerakote® due to the radical increase in uptime and performance:

We began using Cerakote® approximately two years ago. In the past, we have used epoxy coating to protect our steel & ductile iron parts. Most of the failure occurred in the threads which could not be coated. By using Cerakote®, which allows us to coat threads, we have increased the life span of our connections. What was being changed every two to four months is now lasting over eighteen months. We are in the process of changing epoxy coated threaded fittings to Cerakote®, as the steel fittings wear out and are replaced. — Chris Vestal (Production Supervisor; Layline Energy)

Common Coatings and Pre-treatments that Cerakote® replaces:

All paints

Anodizing

Iron Phosphate

Zinc Phosphate

Epoxy Primers

Chromate

Xylan®

Powder Coating

Fusion Bonded Epoxy

Nickel Plating

Salt Bath Nitriding

Galvanizing

PTFE

Substrates Cerakote® can be applied to:

Aluminum – All grades

Mild Steel

Stainless Steel – All grades

Inconel – All grades

Superalloy

Ductile Iron or Cast Iron

Titanium

Magnesium

IF YOUR CURRENT MICROPHONE COATING IS NOT GIVING YOU…

Luxurious color and a striking finish that never fades

Impervious protection against heavy chips, scratches, and dings

Ultra-lightweight applicable for tight tolerance applications (threads, etc.)

Simple yet durable application for aluminum, titanium, polymers and virtually every other potential surface

More than 100 designer colors so you can please even the pickiest musicians

All at a price that’s designed to generate more revenue for your company

…THEN IT’S TIME FOR YOU TO EXPERIENCE THE CERAKOTE® DIFFERENCE.

CERAKOTE®: WE’RE IN THE BUSINESS OF ENHANCING YOUR REPUTATION

As an industry leader in providing high-end ceramic coatings based for automotive, electronics, sports and fitness and even aerospace technology, Cerakote® is no stranger to tackling projects that present a unique set of challenges.

In other words, we protect and enhance the things you care about most. And the music industry is no exception.

That’s why we focus our efforts on creating an easy to apply ceramic coating that puts your microphone exactly where it belongs: front and center, without a single scratch.

Unlike so many other coating materials, Cerakote® is the only ceramic coating that can guarantee thousands of hours of usage without requiring the use of multiple, time-consuming and expensive steps for application.

With traditional methods including powder, anodizing or liquid paint coating, you get…

Uneven color application that varies from microphone to microphone, creating inconsistencies in your product line.

Complex, environmentally unfriendly treatments that require sending your products out for application, potentially delaying your manufacturing process.

Wear and tear from daily usage that shows on products fairly quickly.

Thickly coated treatments that cheapen the overall look and feel of your magnificent microphones.

But with Cerakote®, you can discover…

Batch after batch of color consistency.

A simple V.O.C., heavy metal and hexavalent chrome free, single coat application that increases the speed and efficiency of your coating operation.

Microphones used for thousands of hours of glorious musical magic, without looking worn, that will do your brand justice.

A unique, high-end look and feel finish your clients can’t wait to use and show off.

Bottom line? Cerakote® is your simple, effective solution for adding colorful upgrades to your product line while protecting your business from a quality control nightmare, all in one simple coat.

DRAWBACKS TO TRADITIONAL BICYCLE FINISHES – WHY IS CERAKOTE® BETTER THAN BICYCLE PAINT?

When shopping for mountain or road bicycles, many cyclists can agree that the overall weight of the bike is one of the more important purchasing attributes. Cerakote® is a is a thin film ceramic based single coating (it’s applied at .0005” to .001”) that yields a weight reduction of two to four hundred grams (on average) when compared to powder coat or other paint-based coating applications.

Whether racing or riding for pleasure, road bikes, and off road bikes, especially mountain bikes, are exposed to rugged wear and tear. Cerakote® is a ceramic based performance coating. Cerakote® offers industry leading durability, hardness, and scratch resistance, as well as chemical resistance, that will protect the overall finish of your bike. Cerakote® is not prone to the chipping and blistering commonly found in existing paint finishes, and is not affected by chemicals such as road oil and tar, chain lube and brake fluid.

Additionally, Cerakote’s proprietary formulation provides anti-rust properties that provide exceptional protection for small mechanical parts. In addition, its low coefficient of friction and lubricity means less wear on moving parts which can drastically improve durability while assisting in an overall smoother ride. Reduced friction means improved mechanical efficiency.

Both Cerakote® Elite and H-Series are suitable for the majority of bicycle frame refinishing and/or manufacturing. There are endless possibilities for customization on frames, forks, handlebars, stems, seat posts, rims, hubs, spokes, cassettes and other small parts.

Cerakote Ceramic Coating

C SERIES – AIR CURE

- Formulated to withstand Temperatures up to 1800°F (See individual product descriptions for specific temperature rating)

- Single Component, Ready to Spray

- Direct to Substrate – no primer required

- Over 50 Colours Available

- Excellent UV Stability

- Great Option for Large or Small Parts that cannot be oven cured

- Extremely High Chemical Resistance

- Uses: Automotive, Wheels, Exhaust Systems, Firearms, Architectural, Lighting, Hardware, Optics and Much More

H SERIES – OVEN CURE

- The Unrivaled Leader in Thin Film Protective Coatings in over 100 Colours.

- Perfect for Tight Tolerance Applications and Typically Eliminates the need for Masking.

- Unmatched Corrosion, Chemical and Durability Performance

- Unique Ceramic-Polymer Technology that imparts both Flexibility and Excellent Physical Performance

- Common Uses: Automotive, Firearms, Aerospace, Knives, Eye Wear, Consumer Electronics, Wearables, Salt Water Applications and Much More

V SERIES – OVEN CURE

Best Performing Ultra-High Temperature Coating on the Market

Up to 1800°F High Temp

Industry Leading Heat-Cycled Corrosion Resistance

Withstands Thermal Shock without degrading or losing colour

100% UV Stable

Extremely High Chemical Resistance

Uses: Exhaust Systems, Headers, Turbos, Manifolds, Furnaces, Industrial and Much More

Our Happy Customers

FIND US HERE:

Click on the map to get directions

Send us an Email, click the button below

See lots more images, click the button below

© 2023 Specialists in Cerakote Ceramic Coatings

Privacy Policy

www.ifucantfindit.com

Website Design, Web designer in Kent